Highly precise and accurate parts and components are imperative in every industry to ensure they meet the highest quality standards. These are achieved through numerous capabilities, one of which is manual turning. At Grand Valley Mfg., we offer manual turning with capable work centers and machinists with years of experience to meet our customers’ expectations.

With in-house capabilities and years of experience, our team has a depth of competent machinists who can achieve the products you’re looking for through multiple technologies, which include our manual turning services. We’re ready to undertake any size part configuration or job – big or small. We’re committed to delivering excellence in all our services that are second to none.

What is Manual Turning?

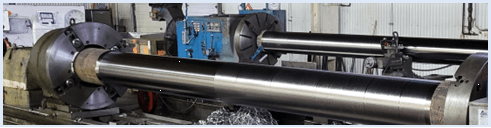

Different processes affect and produce different shapes for various applications. Manual turning refers to a machine that a machinist manually operates and is not under CNC control. The machinist constantly supervises the lathe, a rotating device used to subtractively manufacture the parts or components. The whole process involves a cutting tool, which removes material and shapes a workpiece while it moves.

Our years of experience and work centers used for our turning services allow us to produce pieces made from exotic, difficult to machine materials, that are prone to movement and require close tolerances. The variability of these materials require an experienced, human eye to often ensure success. With a very hands-on nature, our skilled machinists and operators are fully qualified to achieve the products for your specific industry operations.

Benefits of manual turning:

- No more delays: Manual turning doesn’t require any programming, which causes delays if the software isn’t ready. It offers a quicker turnaround since production begins immediately.

- Cost-effective: GVM has made investment in very capable manual lathes that allow for significant stock removal and redundant capabilities that increase productivity and, in turn, produce competitive work center rates.

- Quick delivery: GVM has a very large and redundant library of manual lathes that allow us to accommodate high-volume, burst-speed, and multiple customers at the same time.

Choosing the correct method is crucial for prototypes to parts with incredibly tight tolerances or quick turnarounds. It’s hard to beat the turning services that we offer here at Grand Valley Mfg.

Common Applications of Manual Turning

Manual turning is the perfect choice for conversion machining and preparation machining for downstream processing. Industries like aerospace, medical,, Oil & Gas, Power Generation, , military, and more can benefit from this process since it can quickly achieve the correct dimensions for complex geometry features.

Some of its common applications are as follows:

- Shafting

- Forgings

- Bars

- Pipes

- Hard to machine materials like:

- Inconel

- Titanium

- Stainless Steel

Versatile Solution for Your Varying Projects

GVM has experience machining all materials, specializing in exotic and hard to machine metals like nickel and titanium. regardless of the need or application of your product, Grand Valley Mfg. is experienced and prepared to help.

If it looks like it doesn’t fit, call to speak with one of our technical experts.

Facility Capabilities at a Glance

| Small Shaft Buildings 51 & 52 | Medium Shaft Plant | |

|---|---|---|

| Outside Diameter | 2.00″ – 24.00″ OD | 4″.00 – 48.00″ OD |

| Inside Diameter | 1.180″ – 6.00″ ID | 2.25″ – 40.00″ ID |

| Length | 25′ (300″ ) | 50′ (600″) |

| Weight | 10 Ton Crane | 20 Ton Crane |

| Large Shaft Buildings 82 & 87 | Large Milling Plant | |

|---|---|---|

| Outside Diameter | 4.00″ – 98.00″ OD | 2.00″ – 20′ (240″) Width |

| Inside Diameter | 2.00″ – 60.00″ ID | up to 7′ (84″) Height |

| Length | 70′ (840″) | up to 20′ (240″) Length |

| Weight | 130 Ton Crane | 20 Ton Crane |

Choose Us to be Your Manual Turning Partner

Let us be your partner, and we’ll do our best to manufacture components with utmost quality and focus on delivery in mind. Our skilled professionals have decades of experience in the industry, perfecting our skills and expertise to provide high-quality products to meet our customers specifications.

If you have any questions or want to learn more about our manual turning services, don’t hesitate to contact us today. You may also request a quote and GVM will provide a cost competitive option for any need you may have.