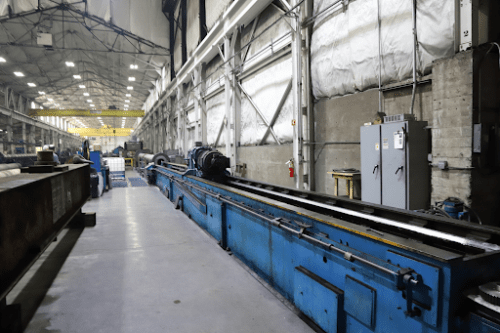

GVM has honing capabilities from very small up to 33”ID’s x 70 feet long, and surface finishes up to 8RA or better. We work with many customers in the hydraulics industry and other companies requiring high quality surface finishes and close tolerances.

GVM is one of the most trusted companies for customers who require honing. GVM can achieve superior finishes and very close tolerances for medium and large components. Rest assured, we can work with your requirements and specifications to meet your project’s needs.

If it looks like it doesn’t fit, call to speak with one of our technical experts.

Facility Capabilities at a Glance

| Small Shaft Buildings 51 & 52 | Medium Shaft Plant | |

|---|---|---|

| Outside Diameter | 2.00″ – 24.00″ OD | 4″.00 – 48.00″ OD |

| Inside Diameter | 1.180″ – 6.00″ ID | 2.25″ – 40.00″ ID |

| Length | 25′ (300″ ) | 50′ (600″) |

| Weight | 10 Ton Crane | 20 Ton Crane |

| Large Shaft Buildings 82 & 87 | Large Milling Plant | |

|---|---|---|

| Outside Diameter | 4.00″ – 98.00″ OD | 2.00″ – 20′ (240″) Width |

| Inside Diameter | 2.00″ – 60.00″ ID | up to 7′ (84″) Height |

| Length | 70′ (840″) | up to 20′ (240″) Length |

| Weight | 130 Ton Crane | 20 Ton Crane |

What is Honing?

Honing is a machining process for the inside diameter of cylindrical parts that uses an abrasive material to achieve high-quality surface finishes and close tolerances. Numerous manufacturing applications require honing to improve a workpiece’s surface, which is imperative in demanding industries.

Some industries we closely work with include Hydraulics, Aerospace, Offshore Oil & Gas, and more. Honing involves using an abrasive material to carefully remove material on a workpiece until the desired finish and dimensional tolerances are attained. The abrasive material usually comes in the form of stones, also known as honing stones.

As the honing stone rubs on a material, it removes the material to alter its size and finish.

Some of its benefits include:

- Very fine surface finishes

- Provides very close dimensional tolerances

- Consistent and repeatable process

The right stones equipped with honing machines can quickly produce the right texture or finish. GVM is proud to offer quality honing services with high accuracy and precision with our work for all industries we serve.

Common Applications of Honing

We specialize in honing alloy steels and many other types of metal, depending on the requirements of our clients. Fortunately, our team has extensive knowledge of the different sectors we work with. Therefore, we can confidently complete any project – big or small.

Some applications of metal honing include:

- Finishing hollow cylindrical parts

- Finishing of Landing Gear

- Hydraulic systems

- Space Components

- Weapons systems

Our expertise in honing allows us to offer unrivaled quality, even for components requiring extremely tight tolerance levels. We always strive to meet our customers’ expectations and deliver top-notch services that they deserve.

ey Manufacturing for Your Honing Needs

Are you looking to improve the surface finish of your parts and/or achieve very close tolerance requirements? Grand Valley Manufacturing is the best choice that can meet your specifications. With our unmatched honing expertise and quality of service, you can trust us to meet all your expectations.

Contact us today, and let’s get started on your project! You may also request a quote, and our team can develop a unique solution tailored to your needs.